Tecnocut

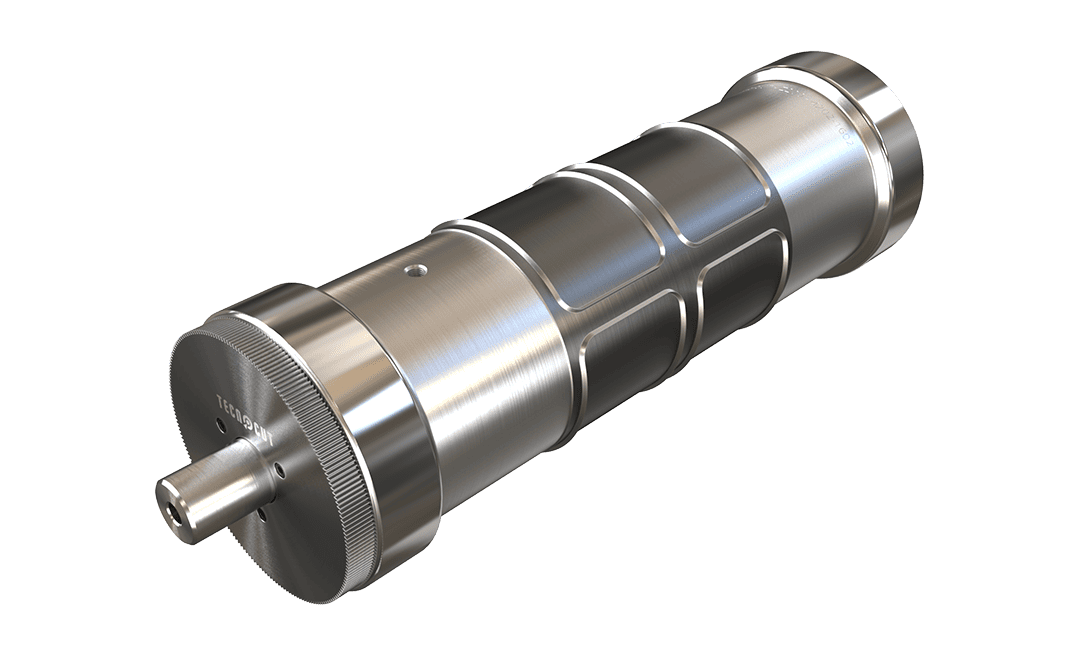

Solid Rotary Dies

Fully custom designed and thought for the most complicated materials

Focus on maximum quality

Solid Rotary Dies

Work with absolute precision

Solid rotary dies are the best option for some jobs: both due to the nature of the material to be cut, as well as the shapes or long runs.

- Se pueden producir con cualquier perfil de corte y altura y en diferentes tipos de acero.

- They are better appropriated to stand up to high pressure applications and more abrasive materials. .

- Unlike flexible dies, they can be “re-sharpened” multiple times.

- There are different coating options: onn-stick coating, hard coating, hard chrome coating, plasma coating and anti-adhesive.

Advantages of our rotary dies

Discover when to use them

Maximum precision

Los distintos tipos de recubrimientos (<0,7 μm) lo convierten en una herramienta de extrema precisión.

100% adaptable

The rotary dies are manufactured on CNC machines individually and according to customer requirements.

Increased durability

The coating of rotary dies prevents both corrosion and frictional wear.

Higher performance

Thanks to the robustness of the product and the protection of the coating, the cutting speed can be increased.

Range of rotary dies

Discover everything we can offer

Standard Rotary Dies

Prepared for cutting large runs and all kinds of self-adhesive and strong materials. Allows multiple regrinds.

Vacuum or Compressed Air

Waste management through compressed air or vacuum.

Variable adjustment of the suction point through the air blade.

Air Ejection

Safe handling of cutting waste through hard rubber inserts in the center of the cutting contours.