Perfect even with the most complex shapes

Desmasystem

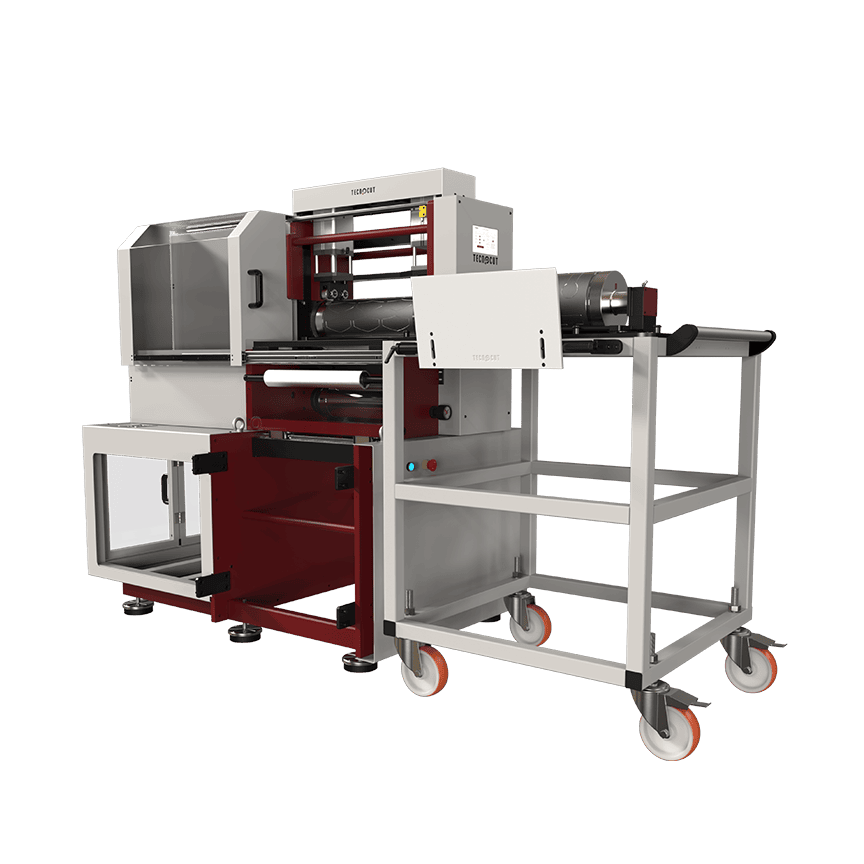

The most versatile waste matrix removal system on the market

Our intelligent tangential stripping system is adaptable to all types of machines. It is equipped with servomotors that allow extremely precise control of the label removal speed, motor torque, acceleration and deceleration.

- Allows to maintain high-speed machine even when working with complex die-cutting shapes.

- The waste re-winder moves horizontally without modifying the distance from the stripping point.

- It has been designed to simplify the set-up, make automated presses, and prevent costly downtime during production .

The perfect solution to the waste matrix removal process

Discover the advantages of the newest Desmasystem

100% Customizable

Completely autonomous system of the machine. It does not affect the software, electronics, or mechanics.

Precision and speed

Maintains speed matrix removal even when working with the most complex shapes or with very thin matrix edges.

Easy operation

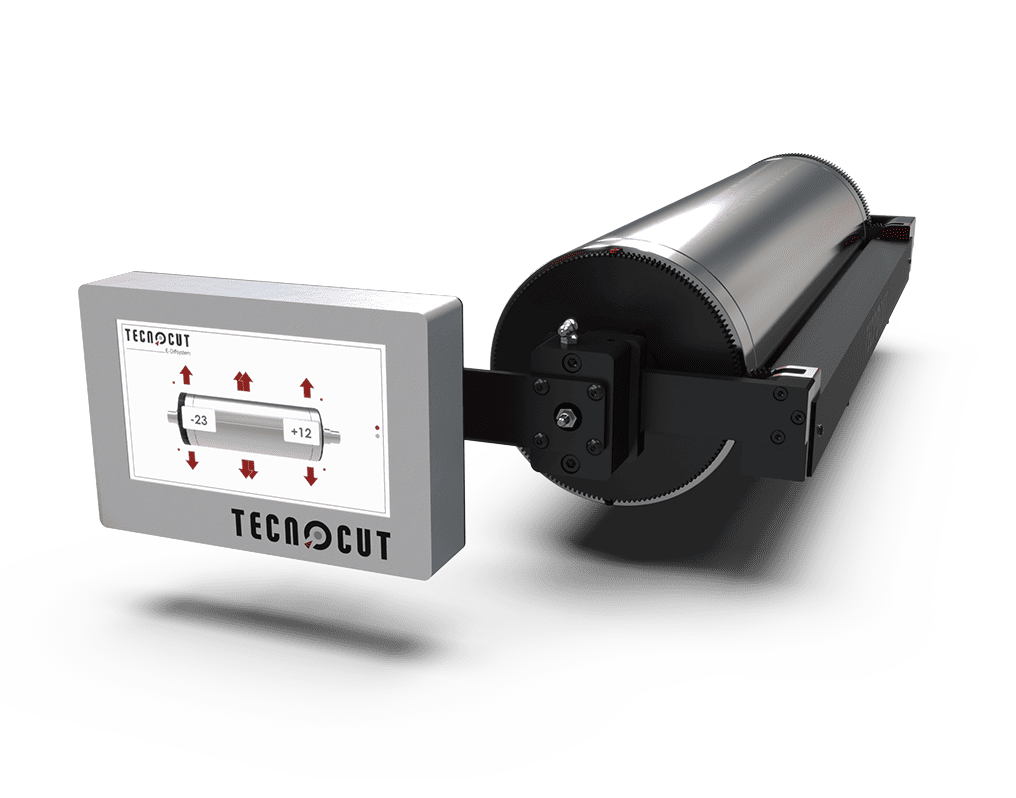

It has an intuitive and very easy-to-use interface. That means that you require a less specialized operator to use it.

Minimize mistakes

Thanks to the Desamsystem’s precision, human and machine errors are substantially reduced.

The fastest waste matrix removal for complex shapes

Increase your production capacity

With the waste matrix removal from Tecnocut Controlled by high-end servo motorsthat allow the control of the speed, engine torque, accelerations, and decelerations in very precise way.

- Opportunity to modify the web path to allow a different angle of detachment of the waste.

- Prevents paper’s breakage and shrinkage.

- Perfect solution to optimize the entire press process and increase productivity.

What customers and partners are saying

Opiniones sobre el desmallado de Desmasystem

Apreciamos mucho la flexibilidad en la personalización de los productos según las demandas del cliente. Como el sistema E-Diffsystem que, gracias a la experiencia de Tecnocut, puede adaptarse a cualquier máquina y permite fácilmente que los clientes aumenten su productividad.

El E-Diffsystem, un producto totalmente electrónico, es fácil de instalar en nuestra maquinaria de troquelado. Es fácil de calibrar y con el sistema táctil tiene un alto rendimiento. El sistema E-Diffsystem permite el control electrónico con precisión micrométrica facilitando el uso de materiales de diferentes espesores y permitiendo siempre un ajuste micra a micra. Es un sistema preciso y estable que se integra muy bien con nuestra tecnología.

Apreciamos mucho la flexibilidad en la personalización de los productos según las demandas del cliente. Como el sistema E-Diffsystem que, gracias a la experiencia de Tecnocut, puede adaptarse a cualquier máquina y permite fácilmente que los clientes aumenten su productividad.

Enrico Firenze & Giovanni Della VedovaSales Manager & CEO at FDM

El E-Diffsystem, un producto totalmente electrónico, es fácil de instalar en nuestra maquinaria de troquelado. Es fácil de calibrar y con el sistema táctil tiene un alto rendimiento. El sistema E-Diffsystem permite el control electrónico con precisión micrométrica facilitando el uso de materiales de diferentes espesores y permitiendo siempre un ajuste micra a micra. Es un sistema preciso y estable que se integra muy bien con nuestra tecnología.

Nicola Lombardi Converting MachineryLombardi Converting Machinery Marketing Director

Do you want more information?

Our team is at your disposal!

Technical characteristics of the Desmasystem

Discover everything we can offer you

Length x Width x Height;

- 1000 mm x 1250 mm x 1200 mm

190 kg

The maximum coil dimensions that the desmasystem accepts are 750mm. (diameter) and between 430-530 mm. (widht).

The total power absorved is 2kw and the air pressure of 6 bar.

It needs 220V, 16 A Single-phase with ground connection

Leq (A) less than 70 dB (A)

- Temperature: 5 to 50ºC

- Humidity: 30 to 90% without condensation.