TECNOCUT

Vacuum unit

Remove the material cutout and keep your machinery in the best condition

Improve the quality of your die cuts

Vacuum unit

Discover how it works

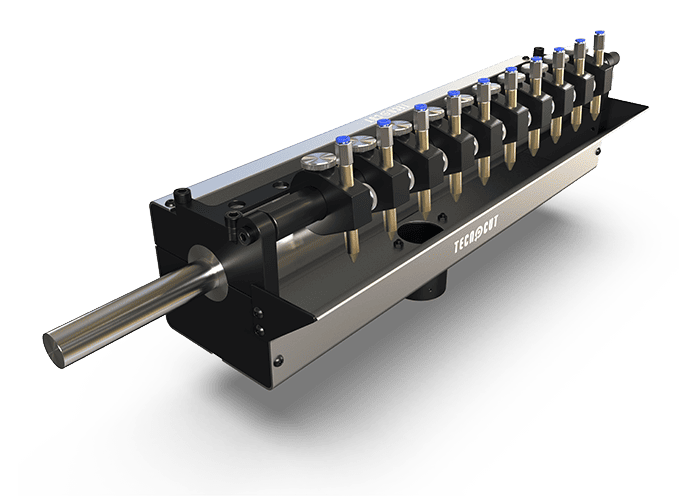

Our vacuum unit allows to remove the material cut out and vacuum it.

- Consiste en varias boquillas de aire a presión, ajustables en posición axial que soplarán el material para asegurar que se desprenda de la pieza original

- En la parte inferior se instala una boca de recogida conectada a un sistema de aspiración que recogerá el desperdicio.

- It prevents that the waste introduces throughout the machine.

- It is tailored manufactured for each machine, depending on the available space.

When is a Vacuum Unit needed?

Allows to work with controlled cutting

Circular cuttings

When cutting in circular forms, the vacuum unit is used to facilitate the separation of the waste.

Interior die cuts

Cuando se realizan recortes en forma de círculos, el extractor de recortes por aire se utiliza para facilitar la separación del trepado.

This is how our vacuum unit works

Discover it step by step

The vacuum unit is usually integrated after the die-cutting phase and Tecnocut also makes the mechanical adaptation.

It has a single pneumatic power supply, from which the air will be distributed to each of the nozzles on the strip. (Image 1). It has a vacuum system in which all the generated waste is collected cleanly. (Image 2) Air nozzles can be manually positioned and in the desired quantity, according to the customer’s needs (Image 3).