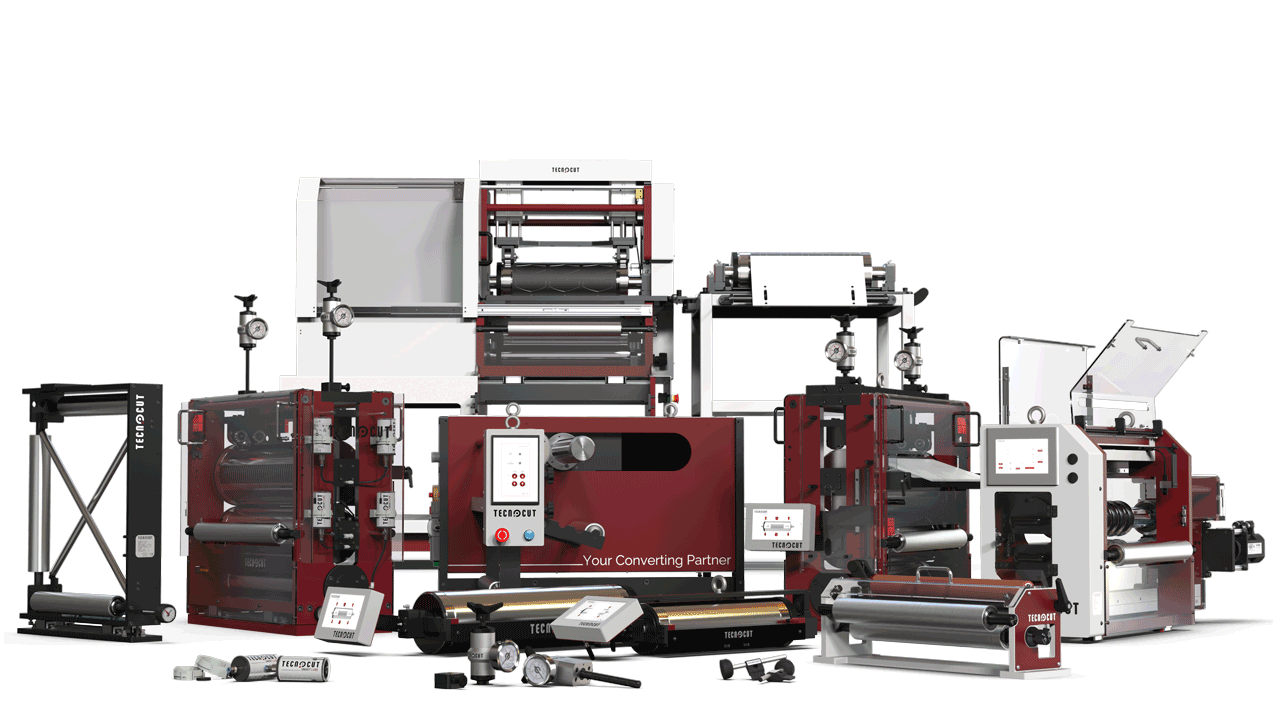

Converting equipment

Here is a selection of our featured products of the month

The best engineering solutions at your service

Everything you need to optimize your production

Discover our die cutting units and converting equipment

“At Tecnocut we focus on designing cutting edge converting equipment and solutions for the label and converting industry. We are committed to bring smart engineering solutions to all our customers and partners, always thinking about maximizing their production.”

Do you need advice from our professionals? Our team is at your disposal!

The best plug-ins for your converting equipment

All of our products are designed to maximize performance

Bearer Wipers

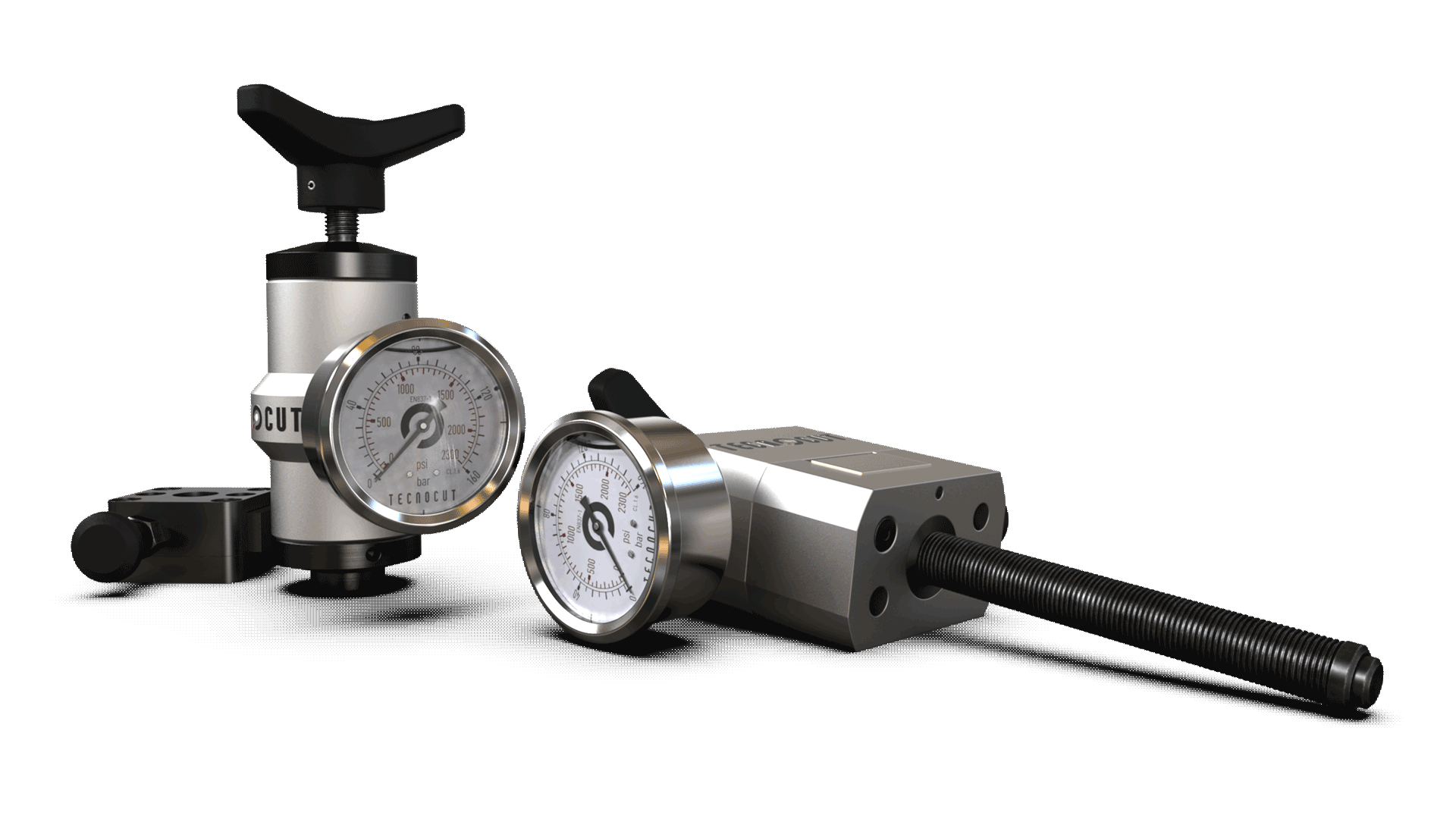

Pressure Gauges

Pressure Bridge

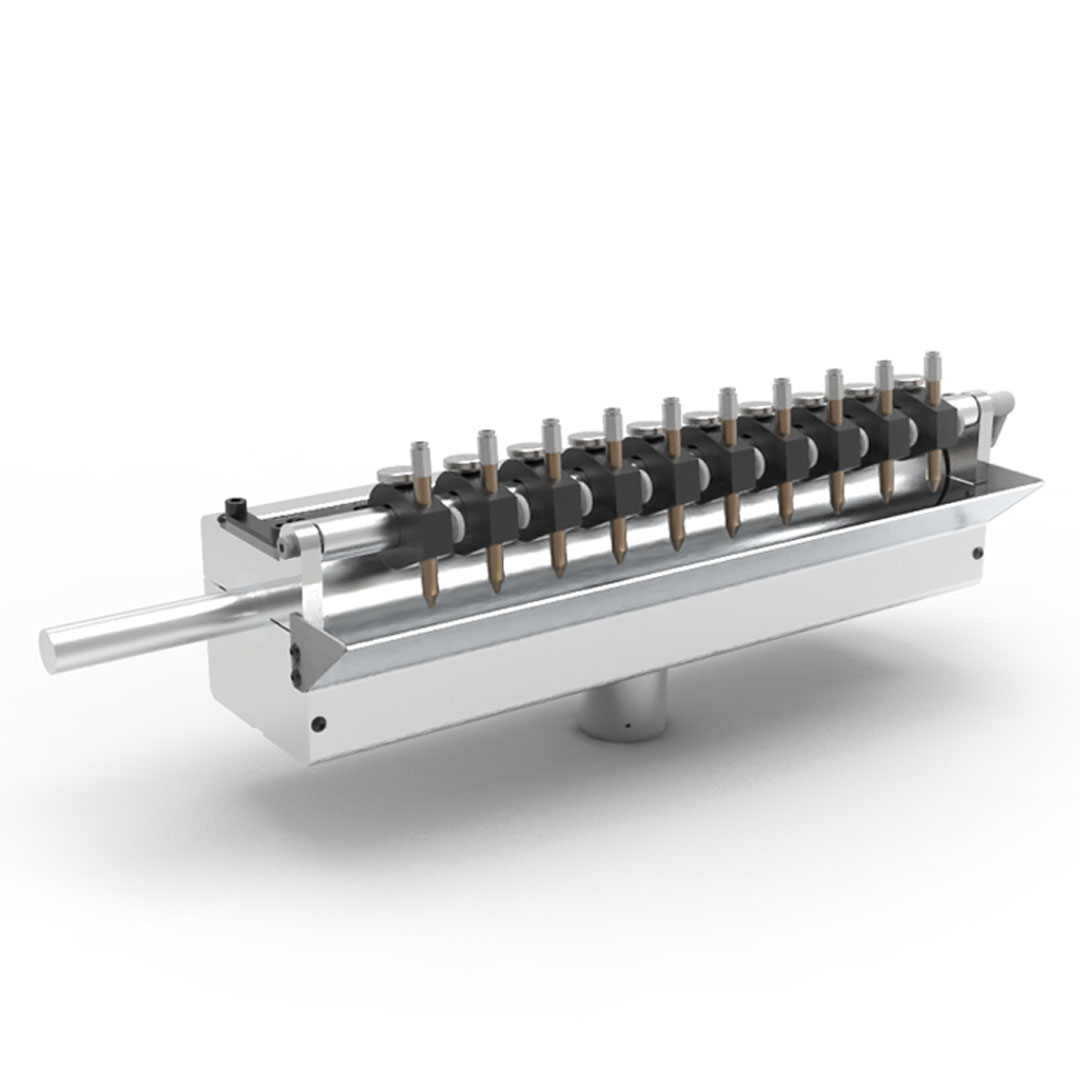

Cylinder Checking Tool

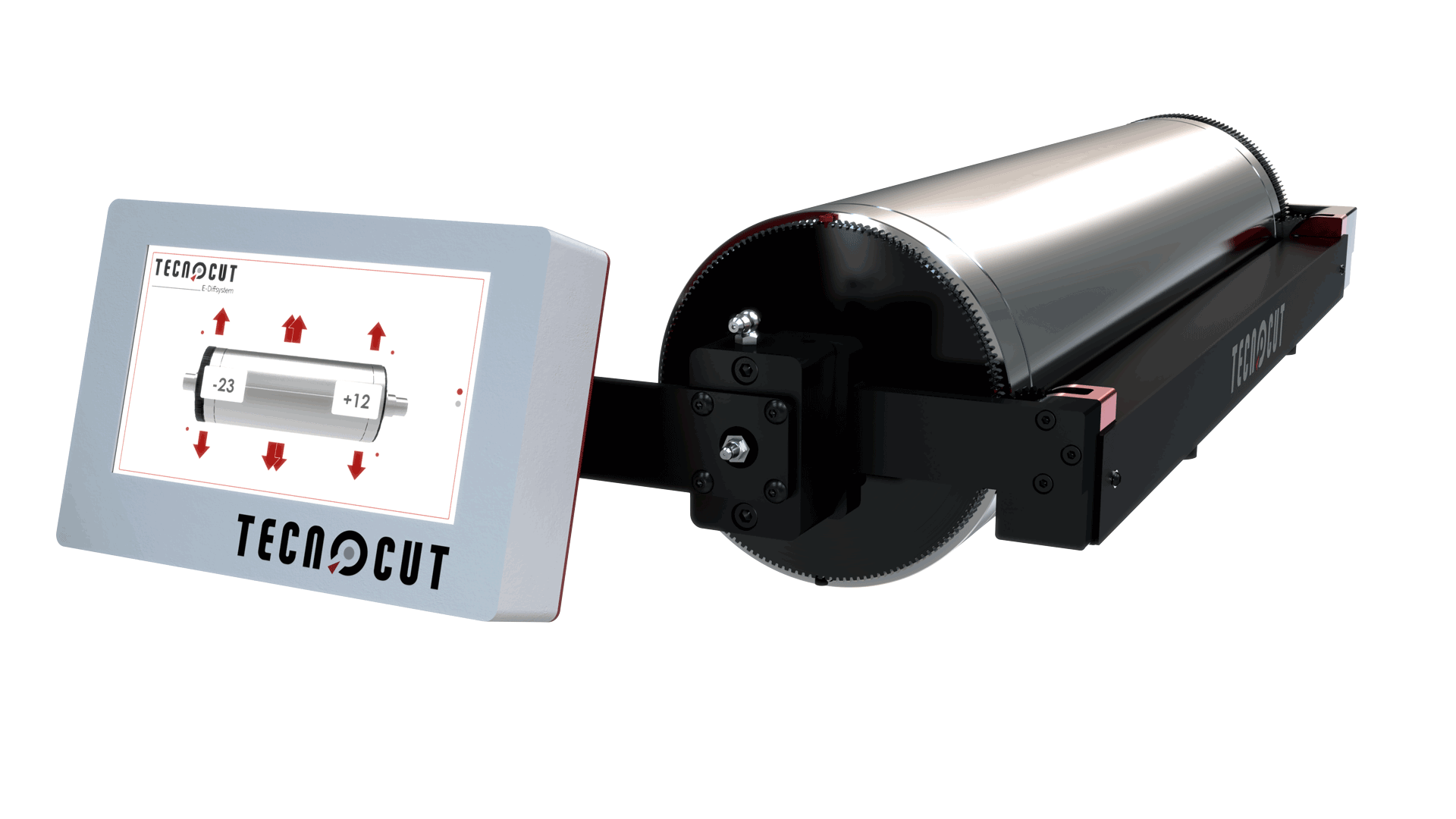

Vacuum Unit

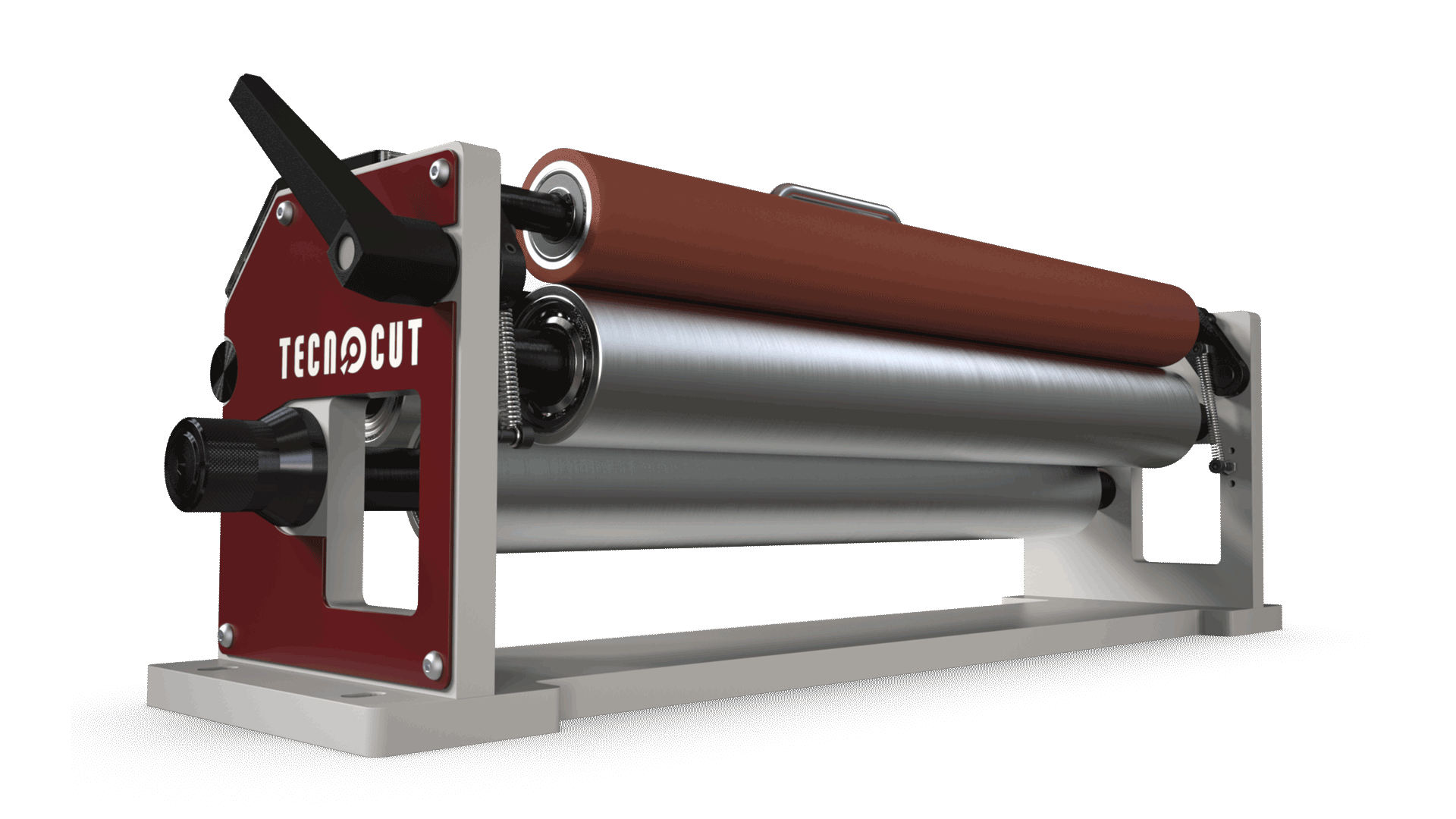

Turns Bars

Smartlube